Activated carbon regeneration kiln

- TaillePersonnalisé en fonction de la capacité

- Matières premièresCoquilles de noix de coco, sciure de bois, charbon,etc

- Température de fonctionnement800°C-1100°C

- Méthode d'activationMéthode physique

- ActivateurVapeur d'eau

- Système de contrôle automatiséPLC

- Méthode de chauffageChauffage externe

Activated carbon regeneration kiln

Activated carbon regeneration kilns are key equipment specifically designed to restore the adsorption properties of saturated activated carbon. Activated carbon regeneration involves removing adsorbates from saturated activated carbon through a specific process, restoring its adsorption capacity. Thermal regeneration is the most common and technically mature activated carbon regeneration method, primarily using heating to desorb or decompose the adsorbate. With increasing environmental protection requirements and awareness of resource recycling, activated carbon regeneration technology is playing an increasingly important role in environmental protection and industrial production.

The primary regeneration method is external heating. The equipment structure and materials used are unique. The principle is that during the drying process, some volatile organic compounds adsorbed are desorbed at high temperatures and converted into waste gas, which is then volatilized along with water vapor. During the carbonization process, most of the organic matter is carbonized and adsorbed within the pores of the activated carbon. During the activation process, the remaining organic compounds are pyrolyzed at a higher temperature. The spent activated carbon is activated in the presence of a defined oxidant (water vapor or a small amount of oxygen), restoring its original pores and creating new ones, achieving the purpose of regenerating the spent activated carbon. External heating regeneration offers the advantages of a high regeneration rate and short regeneration time, making it a mainstream process for activated carbon regeneration.

Raw Materials Arrival

Testing: Upon arrival, waste powdered activated carbon is sampled and tested. Acceptable materials are temporarily stored in a qualified warehouse, while unqualified materials are temporarily stored in an unqualified warehouse before being returned.

Furnace Distribution

Before entering the rotary kiln, waste activated carbon with relatively high chlorine and fluorine contents is mixed with waste activated carbon with relatively low or no chlorine and fluorine contents, based on the spent activated carbon testing results. After the materials are evenly mixed, they are fed into the kiln to ensure relatively stable chlorine and fluorine contents.

Charging

Waste activated carbon in ton bags or drums in the waste activated carbon storage warehouse is placed into the feed hopper using a crane or forklift. The waste powdered activated carbon is then transported into the externally heated rotary kiln via a sealed lifting and unloading device and feeding mechanism.

Regeneration

In the externally heated rotary regeneration kiln, the waste powdered activated carbon slowly moves forward due to the inclination of the kiln and gravity. During this movement, the waste powdered activated carbon comes into contact with the inner tube wall of the kiln. The heat source is provided by the heat source chamber at the rear of the kiln (diesel and liquefied petroleum gas).

Upon entering the front section of the externally heated rotary regeneration furnace (i.e., at temperatures below 600°C), the material exchanges heat with the heat within the furnace, evaporating the water within the waste powdered activated carbon and simultaneously volatilizing some low-boiling-point organic liquids.

After drying in the front section of the externally heated rotary kiln, the material enters the rear section (i.e., at temperatures above 800°C), where a small amount of air and water vapor is introduced. The waste gas adsorbed by the waste powdered activated carbon is then desorbed at high temperatures and reacts with oxygen to produce water vapor, carbon dioxide, and other gases. The regenerated activated carbon settles at the bottom of the rotary kiln, where it is rapidly cooled under negative pressure, collected, packaged, and recycled as finished powdered activated carbon. The regenerated flue gas is first burned in the secondary combustion chamber before entering the exhaust gas treatment system and being discharged through a 35-meter-high exhaust stack.

The externally heated rotary kiln is divided into a waste powdered activated carbon feeding section, a carbonization section, an activation section, and an activated carbon discharge section. A certain amount of waste powdered activated carbon is stored in a feeder above the rotary kiln’s interstitial feed port, creating a natural seal that isolates the furnace atmosphere from the outside world. In the carbonization section, temperature control equipment automatically maintains a temperature of approximately 800°C in each section. In the activation section, the temperature control equipment is spaced an average of 3-4 meters apart, automatically maintaining a temperature of approximately 900°C in each section. At the activated carbon discharge section, the powdered activated carbon is directly collected through a negative pressure quenching and collection system.

In an externally heated rotary regeneration kiln, the waste heat boiler transfers some of the steam generated through a steam delivery pipe to mix with the material. High-pressure injection ensures full contact between the material and the steam, providing the necessary oxygen, fuel gas, and steam. Subsequently, a fan pulls the activated carbon from the furnace head to the furnace tail. The carbonization section begins, carbonizing adsorbed volatile substances and high-boiling-point organic matter remaining in the activated carbon’s pores. These high-boiling-point organic matter is decomposed and carbonized in the adsorbed state, remaining as fixed carbon. The residual carbon produced during the carbonization process is decomposed at 900°C using gases such as carbon dioxide and oxygen. Oxygen is highly oxidizing and can easily cause excessive consumption of the activated carbon, so it is generally not used. Furthermore, oxygen levels must be strictly controlled within the heating regeneration furnace. This project opted for oxidative gas decomposition using steam under an anaerobic environment. The material is activated by steam at high temperatures, gradually opening its pores. The regeneration process is a high-temperature anaerobic process, where organic elements and halogens primarily undergo oxidation reactions to form stable oxides. Heavy metals are primarily present in the activated carbon end product as ash. Some heavy metals, such as Ag, are discharged as oxides in the dust.

The following reactions occur on the activated carbon surface:

C + O₂ = CO₂ 2C + O₂ = 2CO

2CO + O₂ = 2CO₂ N + O₂ = NO₂ C + O₂ = CO₂

C + 2H₂O = 2H₂ + CO₂ C + H₂O = H₂ + CO C + CO₂ = 2CO

Azo compounds = N₂ + free radicals 2H₂ + O₂ = 2H₂O S + O₂ = SO₂

Cl₃ + H₂ = HCl

F₃ + H₂ = HF

These chemical reactions not only vaporize the carbon atoms on the activated carbon’s pore surface, expanding the pores and forming new active surfaces, but also release a large amount of combustible gases. These gases react with the incoming oxygen, releasing a large amount of heat energy, which serves as a heat source to maintain the furnace temperature. The adsorbed substances are carbonized, activated, or burned at high temperatures, completing the regeneration process. If the regeneration process lacks sufficient heat energy, it is supplemented by the heat source chamber at the end of the regeneration furnace. During this process, regenerated exhaust gas is introduced into the secondary combustion chamber for combustion, treated in the exhaust gas treatment facility, and then discharged through a 35m² exhaust stack.

The powdered activated carbon in this project utilizes a countercurrent external heat regeneration method.

Cooling

The regenerated powdered activated carbon, under negative pressure, flows through a sealed feed pipe into a coil collector for cooling. The cooled material is then collected in a cyclone collector and a baghouse before being transferred, packaged, and stored. The coil collector uses recycled water as cooling water, which flows through the inner tubes of the cooler to remove heat from the activated carbon and lower its temperature. The cooling water is recycled and regularly discharged to a wastewater treatment facility for impurity removal before being reused.

Screening and Packaging

After cooling, the regenerated powdered activated carbon is sealed, negatively pressurized, and packaged in bags. After further impurity removal and screening, it is packaged and stored for sale.

Finished Product Storage

The packaged powdered activated carbon is sold directly as a finished product.

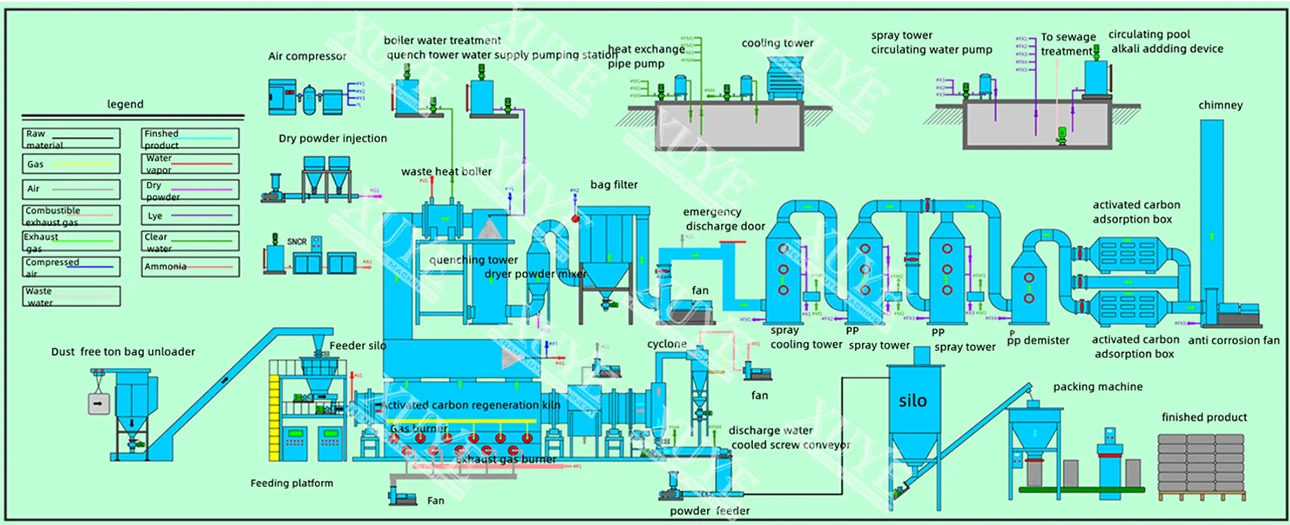

Flue Gas Treatment Process

The main pollutants in regenerated flue gas are dust, acidic components (SO2, NO2, HCl, HF), CO, and dioxins. The flue gas purification system cools, deacidifies, and removes dust from the combustion flue gas, while also controlling harmful substances such as dioxins.

The flue gas purification process is as follows: After combustion in the secondary combustion chamber, the regenerated flue gas undergoes SNCR denitrification at 1100°C. Heat is then recovered in a waste heat boiler to reduce the flue gas temperature to 550°C. The flue gas then enters a quenching tower, where it is atomized with recycled water, ensuring rapid cooling within a temperature range of 550°C to 200°C within one second, effectively preventing the regeneration of dioxins. The flue gas then enters a dry deacidification tower, where absorbents such as quicklime and powdered activated carbon are sprayed in. The absorbents deposit on the bag walls of the bag filter, forming a filter cake. The deposited absorbent continues to absorb gaseous pollutants and dioxins in the flue gas, achieving deacidification and dioxin removal. The absorbent deposits on the bag walls of the bag filter, forming a filter cake. This deposited absorbent then continues to absorb gaseous pollutants from the flue gas. After being removed by the bag filter, the flue gas is drawn by an induced draft fan into a wet deacidification tower, where it is further deacidified by spraying alkali solution. After deacidification, the flue gas enters a demister for water vapor separation. The flue gas then passes through an activated carbon adsorption box to further remove any remaining trace harmful components. The exhaust gas is then heated to 120°C by a flue gas heater, de-whitened, and discharged into the atmosphere through an exhaust stack. The entire flue gas process operates under negative pressure. The flue gas collection system is hard-wired, achieving a 100% collection efficiency.

The flue gas purification system in this project incorporates emergency response measures. First, a spark trap is installed on the main line to prevent sparks from burning and damaging subsequent equipment in the event of a system malfunction (e.g., water outage, equipment damage, etc.). In the event of a malfunction in the main or auxiliary equipment, the rotary kiln immediately stops and an alarm is sounded. The bag bypass valve opens, and the flue gas remaining in the flue is sprayed and demisted in an alkali spray tower before entering an activated carbon adsorption tower for treatment. It is then discharged through an induced draft fan.

After combustion in the secondary combustion chamber, the regenerated flue gas is processed through a combination of SNCR denitrification, quenching, dry deacidification, dry dioxin removal, bag dust removal, wet deacidification, water separation, activated carbon adsorption, and flue gas reheating before being discharged through the exhaust stack.

Activated Carbon Regeneration Kiln Parameter

| Matières premières | Coconut shell/nut shell/cylindrical activated carbon | Powdered activated carbon |

| Capacité | 5-20t/d | 3-10t/d |

| preprocessing | Screening and impurity removal | Screening and impurity removal |

| Regeneration kiln heating method | Internal heating/external heating | external heating |

| Regeneration carbon rate | 80-90% | 50-65% |

| Particle size requirements | 1-10mm | 0-1mm |

| fuel | natural gas/oil | |

| Regeneration effect (compared with original activated carbon) | 50-100% | |

| Regeneration temperature | 800-950ºC | |

| Finished product cooling method | Indirect water cooling | |

| Activateur | Water vapor/flue gas | |

| Waste gas treatment process | Secondary combustion, SNCR, waste heat boiler, quenching, dry deacidification, pulse dust removal, wet deacidification, defogging, etc. | |

Activated Carbon Regeneration Kiln Video

XUYE EQUIPMENT

XUYE EQUIPMENT