Biochar stove

- الحجممخصص حسب السعة

- المواد الخامWood, bamboo, coconut shells, fruit shells, rice husks, etc.

- درجة حرارة التشغيل300℃ – 800℃ (adjustable according to process requirements)

- Production methodمستمر

- Furnace materialCarbon steel, stainless steel, ceramic fiber insulation material

- طريقة التسخينGas heating

- AutomationPLC control (optional)

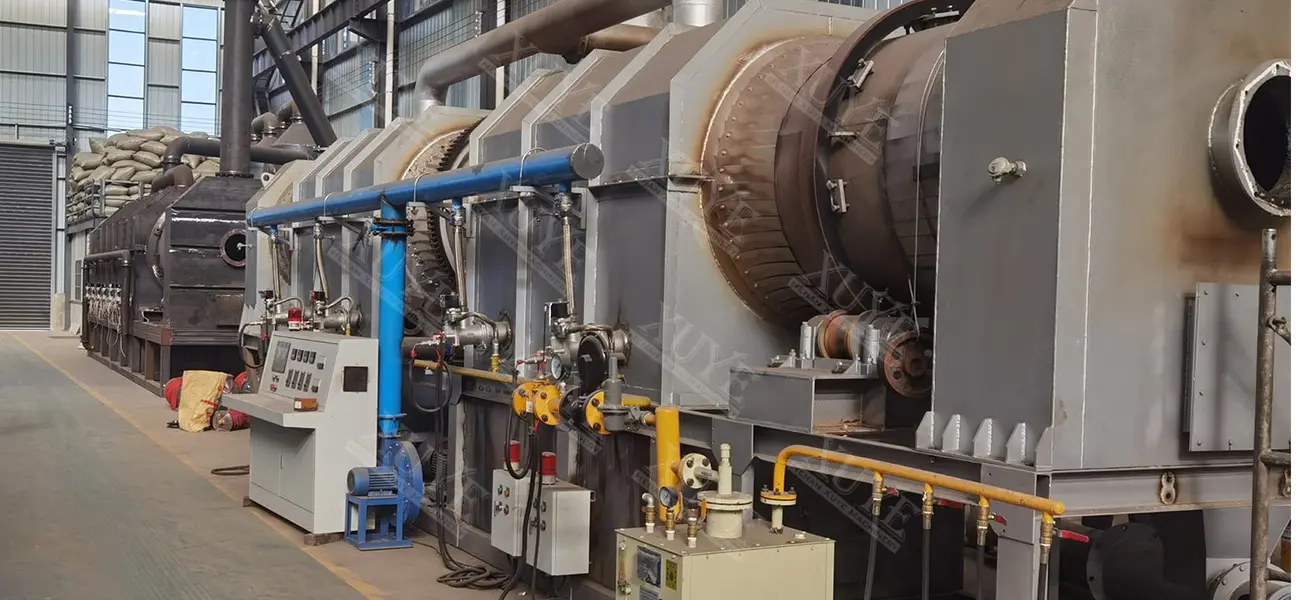

Biochar stove

Biochar stove is an innovative piece of equipment designed to convert agricultural and forestry residues into biochar through pyrolysis. Unlike traditional stoves, a biochar stove produces both clean energy for cooking or heating and high-quality biochar for soil enhancement. This dual-purpose technology makes it a sustainable solution for rural households, farms, and eco-friendly industries worldwide.

Whether you are looking to reduce waste, improve soil fertility, or lower carbon emissions, investing in a biochar making stove can bring long-term environmental and economic benefits.

What is a Biochar Stove?

A biochar stove, also known as a biochar making stove or biochar furnace, operates on the principle of pyrolysis. It heats organic biomass such as crop residues, wood chips, coconut shells, rice husks, or sawdust in an oxygen-limited environment. Instead of complete combustion, this process creates biochar while simultaneously producing usable heat or syngas.

Key features include:

- High conversion efficiency – Maximizes biomass-to-biochar yield.

- Low emissions – Reduces smoke and greenhouse gases compared to open burning.

- Dual use – Provides thermal energy for cooking/heating and generates biochar.

- Cost-effective – Uses low-cost biomass waste as feedstock.

Benefits of Using a Biochar Stove

- Renewable Energy Source

A biochar stove produces clean heat for cooking, drying crops, or small-scale heating applications. - Soil Improvement

The biochar produced enhances soil aeration, water retention, and nutrient absorption. - Carbon Sequestration

Biochar locks carbon into the soil for centuries, reducing overall CO₂ emissions. - Economic Value

Farmers and businesses can use biochar as a soil conditioner, livestock feed additive, or sell it commercially. - Waste Reduction

Agricultural residues and forestry by-products are converted into valuable resources.

Applications of Biochar Stove

A biochar stove is versatile and can be used in different industries:

- Agriculture – Enhancing soil fertility and crop yield.

- Forestry – Utilizing wood waste effectively.

- Livestock Farming – Biochar added to feed reduces odor and improves digestion.

- Renewable Energy – Producing biochar while supplying clean heat.

- Environmental Projects – Community-driven carbon reduction initiatives.

Types of Biochar Stoves

- Household Biochar Stoves – Compact, portable, designed for small-scale cooking and home gardening biochar production.

- Mobile Biochar Stoves – Easy-to-move systems suitable for farms and rural communities.

- Industrial Biochar Stoves – Large-capacity stoves designed for continuous production in commercial settings.

How a Biochar Stove Works

- Feeding Biomass – Agricultural waste, sawdust, or shells are loaded into the chamber.

- Pyrolysis Heating – The stove heats biomass in low-oxygen conditions.

- Gas Collection – Syngas is released and used as a heat source.

- Biochar Output – Solid carbon-rich biochar is collected for agricultural or industrial use.

This process ensures maximum energy recovery and sustainable biochar production.

Choosing the Right Biochar Stove

When selecting a biochar stove, consider the following factors:

- Capacity & Output – Household or industrial needs.

- Feedstock Compatibility – Wood, rice husks, coconut shells, or mixed biomass.

- كفاءة الطاقة – High conversion rate and low fuel consumption.

- Mobility – Fixed or portable design.

- Budget – Affordable household models vs. advanced industrial equipment.

Why Invest in a Biochar Stove?

- Contribute to sustainable farming.

- Support carbon-negative technology.

- Utilize local agricultural waste effectively.

- Improve food security through better soil fertility.

- Create an additional income stream from biochar sales.

Biochar stove Parameter

| الطراز | XY-800 | XY-1000 | XY-1200 | XY-1500 | XY-1800 | XY-2000 |

| Number of cylinder layers | Single | Single | Double | Double | Double | Double |

| Cylinder diameter | 800mm | 1000mm | 1200/700mm | 1500/900mm | 1800/1200mm | 2000/1500mm |

| الطاقة الاستيعابية | 200-300kg/h | 300-400kg/h | 450-600kg/h | 600-800kg/h | 800-1000kg/h | 1000-1200kg/h |

| Cylinder material | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L |

| Temerature | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC |

| Carbonization time | 20-60min | 20-60min | 20-60min | 20-60min | 20-60min | 20-60min |

| Raw material particle size | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm |

| طريقة التسخين | indirect heating | indirect heating | indirect heating | indirect heating | indirect heating | indirect heating |

| Operation mode | continuously working | continuously working | continuously working | continuously working | continuously working | continuously working |

| Control method | PLC control | PLC control | PLC control | PLC control | PLC control | PLC control |

Biochar Stove Video

معدات XUYE EQUE

معدات XUYE EQUE