Gold purification activated carbon making machine

- TamanhoPersonalizado de acordo com a capacidade

- Matéria-primaCascas de coco, serragem, carvão, etc.

- Temperatura operacional800°C-1100°C

- Método de ativaçãoMétodo físico

- AtivadorVapor de água

- Sistema de controle automatizadoPLC

- Método de aquecimentoAquecimento interno

Gold purification activated carbon making machine

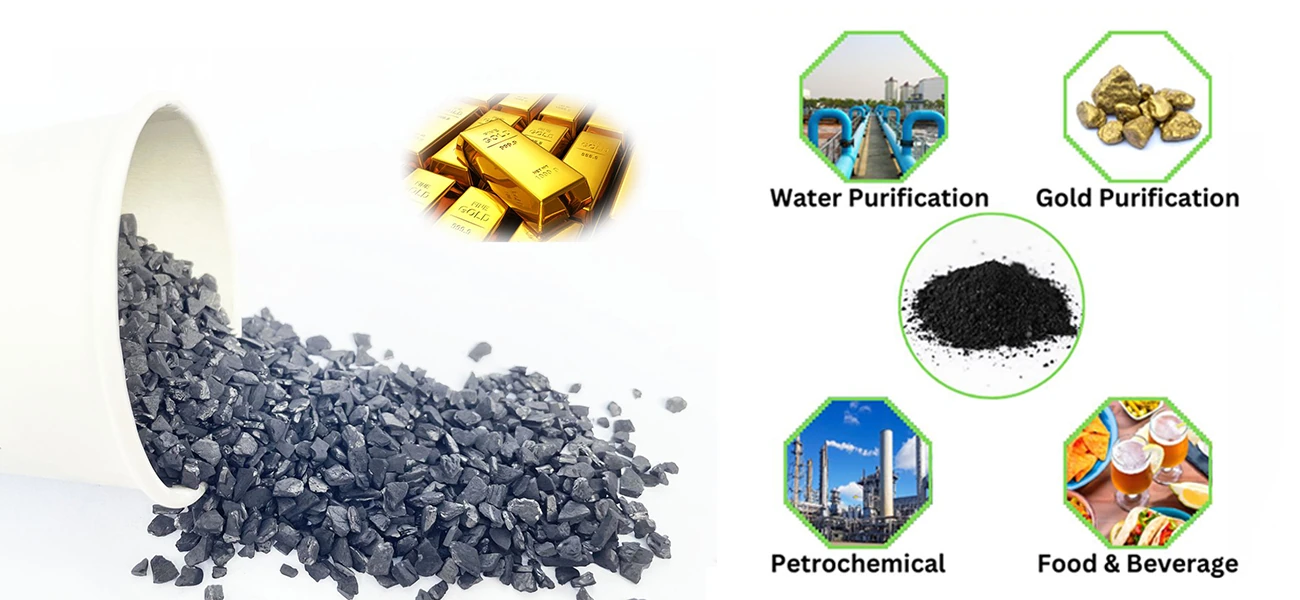

Gold purification activated carbon is a specialized type of activated carbon used in the gold extraction and refining industry. It has a high surface area, excellent adsorption capacity, and uniform pore structure, enabling it to adsorb gold ions from leach solutions efficiently.

O Gold Purification Activated Carbon Making Machine is designed to produce high-quality activated carbon suitable for gold recovery processes, including cyanidation and other leaching methods. The equipment converts raw materials such as coconut shells, coal, wood, or palm shells into activated carbon optimized for precious metal adsorption.

What is a Gold Purification Activated Carbon Making Machine?

A Gold Purification Activated Carbon Making Machine is industrial equipment used to produce activated carbon tailored for the gold recovery process. This activated carbon must have:

- High adsorption rate for gold ions

- Low impurity content

- Uniform granule or pellet size

- Resistance to harsh chemical environments

The machine integrates:

- Carbonização

- Activation (steam or chemical)

- Granulation

- Cooling and packaging

Raw Materials for Gold Purification Activated Carbon

Common raw materials include:

- Coconut shells – microporous, high hardness, and excellent adsorption

- Coal – anthracite or bituminous coal with high carbon content

- Bamboo and wood – biomass options with mesoporous structures

- Palm kernel shells – renewable and hard material suitable for gold adsorption

Pre-treatment involves:

- Crushing to uniform particle size

- Drying to reduce moisture below 10%

- Screening to remove impurities

Working Principle of Gold Purification Activated Carbon Making Machine

Step 1: Crushing and Drying

Raw materials are crushed and dried to ensure uniform particle size and moisture control for efficient carbonization.

Step 2: Carbonization

Crushed material is heated in a carbonization furnace under low-oxygen conditions. Volatile compounds are removed, leaving carbon-rich char suitable for activation. Rotary kilns or batch furnaces can be used depending on production capacity.

Step 3: Activation

- Steam Activation – high-temperature steam reacts with carbon char to create micropores for gold adsorption

- Chemical Activation – chemicals such as KOH or H₃PO₄ enhance the surface area and adsorption capacity

Step 4: Granulation and Screening

Activated carbon is granulated into uniform sizes or pellets to ensure optimal performance in gold leaching tanks. Screening ensures consistent particle size and quality.

Step 5: Cooling and Packaging

Finished activated carbon is cooled to prevent oxidation, stabilized, and packaged for gold purification applications.

Structure of a Gold Purification Activated Carbon Making Machine

A complete production line includes:

- Crusher & Grinder – reduces raw material particle size

- Drying System – removes moisture efficiently

- Forno de carbonização – high-temperature pyrolysis

- Forno de ativação – steam or chemical activation system

- Granulation and Pelletizing Unit – ensures uniform size and shape

- Cooling System – prevents oxidation and preserves adsorption properties

- Screening System – maintains particle uniformity

- Dust Collection System – environmental compliance

- Packaging Unit – prepares activated carbon for shipment

Applications of Gold Purification Activated Carbon

- Gold Recovery in Mining

- Adsorbs gold ions from cyanide or other leach solutions

- Used in fixed-bed adsorption tanks

- Precious Metal Refining

- Recovers gold from low-grade ores or secondary resources

- Used in refineries for purifying gold solutions

- Industrial Applications

- Can also adsorb silver, platinum, and other precious metals

- Acts as a catalyst support in chemical processes

Advantages of Gold Purification Activated Carbon Making Machine

- High Adsorption Efficiency – microporous and mesoporous structure tailored for gold ions

- Durable Product – high mechanical strength reduces breakage during leaching

- Continuous Production – rotary kilns allow industrial-scale output

- Energy-Efficient – optimized heat recovery reduces operational costs

- Environmentally Friendly – dust and flue gas treatment

- Customizable Granules – adjustable pellet or granule size for specific gold recovery systems

How to Choose the Right Gold Purification Activated Carbon Making Machine

- Production Capacity – based on mining or refinery scale

- Raw Material Compatibility – coconut shell, coal, bamboo, or palm kernel shells

- Eficiência energética – models with heat recovery systems reduce costs

- Nível de automação – fully automatic lines reduce labor and ensure consistent quality

- Manufacturer Reliability – technical support and after-sales service are crucial

- Compliance – machine must meet environmental and safety regulations

Gold purification activated carbon making machine Parameter

| Item | Modelo | Capacidade | Tamanho |

| Forno de ativação rotativa (tipo de calor interno) | Φ1,5m×12m | 1-2t/d | 16000*2300*4000mm |

| Φ1,5m×15m | 2-3t/d | 20000*2700*4500mm | |

| Φ2.0m×18m | 4-5t/d | 22000*3000*4500mm | |

| Φ2,6m×20m | 5-8t/d | 26000*3600*5000mm |

Gold purification activated carbon making machine Video

EQUIPAMENTO XUYE

EQUIPAMENTO XUYE