Coconut shell charcoal making machine

- 크기용량에 따라 맞춤 설정

- 원재료Wood, bamboo, coconut shells, fruit shells, rice husks, etc.

- 작동 온도300℃ – 800℃ (adjustable according to process requirements)

- Production methodContinuous

- Furnace materialCarbon steel, stainless steel, ceramic fiber insulation material

- 가열 방법Gas heating

- AutomationPLC control (optional)

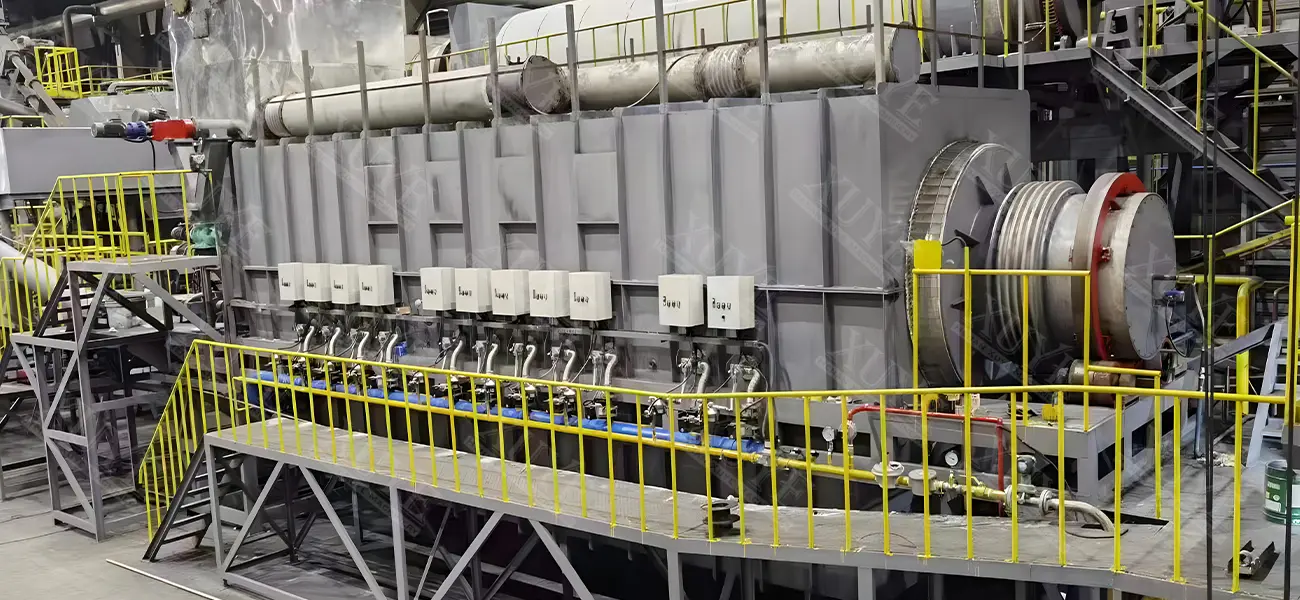

Coconut shell charcoal making machine

Coconut shells, often treated as agricultural waste, are in fact one of the most valuable biomass resources for producing high-quality charcoal. With the rising global demand for BBQ charcoal, activated carbon, and industrial fuel, the coconut shell charcoal making machine has become a key investment for eco-friendly energy production.

This advanced equipment adopts pyrolysis technology to convert raw coconut shells into charcoal under high temperature and limited oxygen conditions. Compared with traditional charcoal kilns, the modern coconut shell charcoal production equipment is energy-saving, environmentally friendly, and capable of producing multiple outputs such as charcoal, wood vinegar, tar, and syngas.

By turning coconut shell waste into a profitable resource, the coconut shell charcoal machine not only generates economic value but also contributes to waste recycling, renewable energy, and sustainable development.

What is a Coconut Shell Charcoal Making Machine?

A coconut shell charcoal making machine is a specialized piece of equipment that uses a process called pyrolysis to convert coconut shells into charcoal in an oxygen-deficient environment. Unlike traditional burning methods, pyrolysis prevents complete combustion, resulting in high charcoal yield and minimizing harmful emissions.

This machine is designed to handle the unique properties of coconut shells, which are hard and dense, making them ideal for producing charcoal with a high fixed carbon content.

How Does the Coconut Shell Charcoal Production Process Work?

The operation of a coconut shell charcoal making machine is a continuous and automated process, which can be broken down into several key stages:

- Pre-processing & Feeding: Coconut shells are crushed into small, uniform pieces (typically 10-20mm) to ensure efficient carbonization. These pieces are then automatically conveyed into the pyrolysis reactor.

- Pyrolysis (Carbonization): The reactor is heated to a high temperature (typically between 400°C and 800°C) in the absence of oxygen. Under these conditions, the coconut shells decompose, releasing volatile gases and leaving behind solid carbon—the charcoal.

- Gas Recycling and Reburning: The combustible gases released during pyrolysis are not wasted. They are purified and recycled back into the reactor as a source of heat, significantly reducing the need for external fuel and making the system self-sustaining and energy-efficient.

- Cooling and Discharge: The newly formed charcoal is cooled down through a sealed water cooling system to prevent it from igniting upon contact with air. Finally, the finished coconut shell charcoal is automatically discharged, ready for packaging or further processing.

Key Benefits of Investing in a Coconut Shell Charcoal Machine

Why should you consider this investment? The benefits are substantial:

- High Profitability & ROI: Coconut shell charcoal is in high demand for various applications (see below), commanding a good market price. The raw material (coconut shells) is often low-cost or even free, leading to a high return on investment.

- Eco-Friendly & Sustainable: This process effectively tackles agricultural waste, reducing landfill and open burning. The closed-loop system minimizes smoke and pollution, contributing to a cleaner environment.

- Versatile End Products: The primary product isn’t just ordinary charcoal. Coconut shell charcoal is known for its:

- High calorific value

- Low moisture and ash content

- Long burning time

It’s used as BBQ charcoal, industrial fuel, and as a raw material for producing activated carbon.

- Additional By-Product: Biofuel: The pyrolysis process also produces valuable by-products like wood vinegar and tar, which can be sold as industrial chemicals or biofuels, adding extra revenue streams.

- Safety and Automation: Modern machines are equipped with advanced safety features and PLC control systems, making operation safe, simple, and requiring minimal manual labor.

What Are the Applications of Coconut Shell Charcoal?

The final product from your coconut charcoal making machine has diverse markets:

- BBQ and Hookah Charcoal: Preferred for its high heat, low smoke, and pleasant aroma.

- Industrial Fuel: Used in metallurgy, boiler heating, and other industries requiring high-temperature fuel.

- Activated Carbon Production: This is a high-value market. Coconut shell charcoal is the primary raw material for high-quality activated carbon used in water purification, air filters, and gold recovery.

- Soil Amendment: Crushed charcoal can be used as a biochar to improve soil fertility.

How to Choose the Right Coconut Shell Charcoal Making Plant?

Selecting the right machine is crucial for your success. Consider these factors:

- Capacity (Batch vs. Continuous): Determine your daily or hourly processing needs. We offer models from small batch types to fully continuous carbonization systems.

- Reactor Design: The quality and durability of the reactor directly impact the machine’s lifespan and efficiency.

- Safety Features: Look for pressure gauges, temperature alarms, and automatic sealing systems.

- After-Sales Service: Ensure the supplier provides installation guidance, training, and reliable technical support.

Coconut shell charcoal making machine Parameter

| 모델 | XY-800 | XY-1000 | XY-1200 | XY-1500 | XY-1800 | XY-2000 |

| Number of cylinder layers | Single | Single | Double | Double | Double | Double |

| Cylinder diameter | 800mm | 1000mm | 1200/700mm | 1500/900mm | 1800/1200mm | 2000/1500mm |

| 용량 | 200-300kg/h | 300-400kg/h | 450-600kg/h | 600-800kg/h | 800-1000kg/h | 1000-1200kg/h |

| Cylinder material | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L |

| Temerature | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC |

| Carbonization time | 20-60min | 20-60min | 20-60min | 20-60min | 20-60min | 20-60min |

| Raw material particle size | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm |

| 가열 방법 | indirect heating | indirect heating | indirect heating | indirect heating | indirect heating | indirect heating |

| Operation mode | continuously working | continuously working | continuously working | continuously working | continuously working | continuously working |

| Control method | PLC control | PLC control | PLC control | PLC control | PLC control | PLC control |

Coconut shell charcoal making machine Video

XUYE 장비

XUYE 장비