Continuous carbonization furnace

- TallaPersonalizado según la capacidad

- Materia primaWood, bamboo, coconut shells, fruit shells, rice husks, etc.

- Temperatura de funcionamiento300℃ – 800℃ (adjustable according to process requirements)

- Production methodContinuous

- Furnace materialCarbon steel, stainless steel, ceramic fiber insulation material

- Método de calentamientoGas heating

- AutomationPLC control (optional)

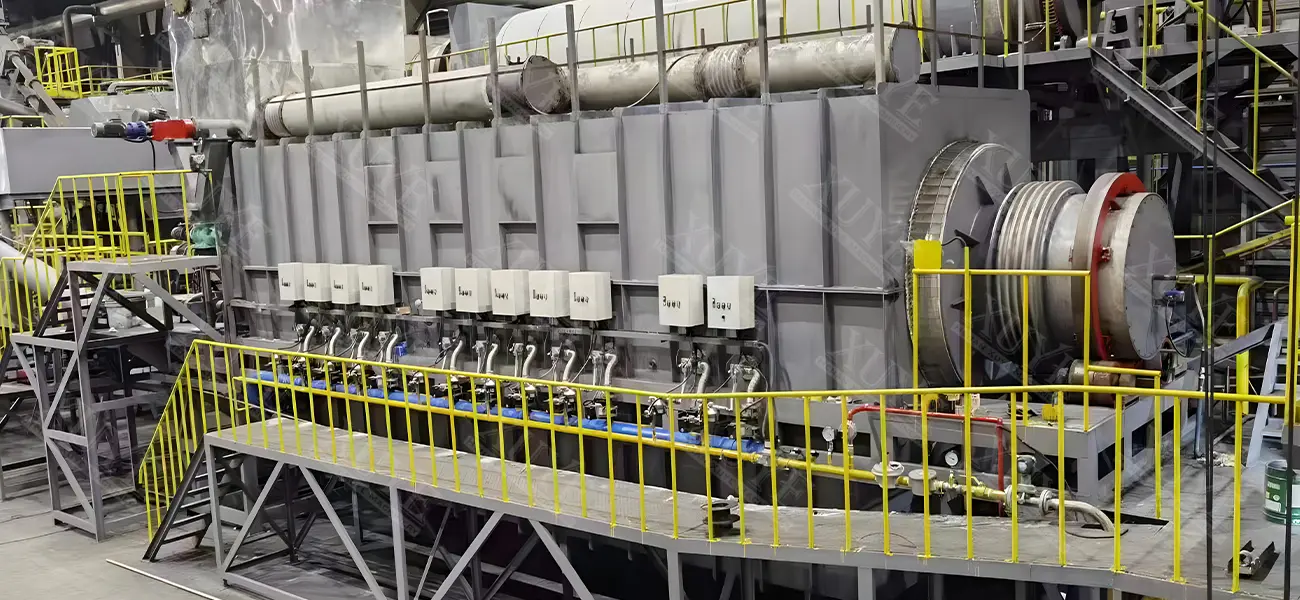

Continuous carbonization furnace

A continuous carbonization furnace is a modern biomass processing machine designed for the continuous production of charcoal and biochar. Unlike traditional batch-type furnaces, this equipment allows uninterrupted feeding and discharging, ensuring high efficiency, stable quality, and large-scale output.

With advanced pyrolysis technology, the continuous carbonization furnace transforms raw materials such as wood, coconut shells, bamboo, sawdust, rice husks, palm shells, and other agricultural waste into high-value charcoal, biochar, and activated carbon precursors. This eco-friendly process helps reduce waste, recycle biomass, and support sustainable energy development.

Working Principle of Continuous Carbonization Furnace

En continuous carbonization furnace works under an oxygen-limited pyrolysis process. The main steps include:

- Automatic Feeding – Biomass raw materials are fed continuously into the carbonization chamber through a conveyor or screw feeder.

- High-Temperature Carbonization – Materials are heated in the furnace (300–800°C) under low-oxygen conditions.

- Gas Collection and Recycling – Combustible gas generated during carbonization is collected and reused as the furnace’s heating source, reducing fuel costs.

- Continuous Discharging – The finished charcoal or biochar is discharged automatically from the outlet, maintaining uninterrupted operation.

This closed-loop system ensures energy-saving operation, low emissions, and consistent product quality.

Features of Continuous Carbonization Furnace

- 24/7 Operation – Supports uninterrupted production with high efficiency.

- Energy Recycling System – Reuses pyrolysis gas as fuel, lowering energy consumption.

- Environmental Protection – Equipped with smoke purification devices to ensure clean emission.

- Automation Control – PLC or smart control system ensures stable performance.

- High Output – Suitable for industrial-scale charcoal production.

- Durable Design – Made of high-quality steel and refractory materials for long service life.

Advantages of Continuous Carbonization Furnace

Choosing a continuous carbonization furnace offers several key benefits:

- Large Production Capacity – Ideal for mass production of charcoal and biochar.

- Stable Quality – Ensures uniform heating and consistent carbon content.

- Energy Efficiency – Uses its own by-product gas to minimize external fuel.

- Labor Saving – Fully automated operation requires minimal manpower.

- Eco-Friendly – Complies with international environmental standards.

Applications of Continuous Carbonization Furnace

En continuous carbonization furnace is widely used in multiple industries:

- Charcoal production for barbecue, cooking, and heating.

- Biochar for agriculture – Improves soil fertility, water retention, and crop yield.

- Industrial carbon – Used in metallurgy, smelting, and chemical industries.

- Precursor for activated carbon – Applied in water treatment, air purification, and gold recovery.

- Renewable energy projects – Supports circular economy and green energy initiatives.

Raw Materials Suitable for Continuous Carbonization Furnace

This furnace is highly versatile and can process a wide range of biomass materials:

- Wood logs and branches

- Bamboo waste

- Coconut shells

- Palm shells and kernel shells

- Rice husks

- Sawdust and wood chips

- Peanut shells, walnut shells, and other nut shells

Why Choose Our Continuous Carbonization Furnace?

When investing in a continuous carbonization furnace, selecting a reliable manufacturer is critical. Our furnaces offer:

- Customized design – Available in different capacities to meet various production needs.

- Advanced technology – Optimized for high efficiency and long-term stability.

- After-sales service – Installation guidance, operator training, and maintenance support.

- Competitive pricing – Affordable cost with high return on investment.

Continuous carbonization furnace Parameter

| Modelo | XY-800 | XY-1000 | XY-1200 | XY-1500 | XY-1800 | XY-2000 |

| Number of cylinder layers | Single | Single | Double | Double | Double | Double |

| Cylinder diameter | 800mm | 1000mm | 1200/700mm | 1500/900mm | 1800/1200mm | 2000/1500mm |

| Capacidad | 200-300kg/h | 300-400kg/h | 450-600kg/h | 600-800kg/h | 800-1000kg/h | 1000-1200kg/h |

| Cylinder material | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L |

| Temerature | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC |

| Carbonization time | 20-60min | 20-60min | 20-60min | 20-60min | 20-60min | 20-60min |

| Raw material particle size | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm |

| Método de calentamiento | indirect heating | indirect heating | indirect heating | indirect heating | indirect heating | indirect heating |

| Operation mode | continuously working | continuously working | continuously working | continuously working | continuously working | continuously working |

| Control method | PLC control | PLC control | PLC control | PLC control | PLC control | PLC control |

Continuous carbonization furnace Video

EQUIPO XUYE

EQUIPO XUYE