Search the whole station

Coconut shells, often treated as agricultural waste, are in fact one of the most valuable biomass resources for producing high-quality charcoal. With the rising global demand for BBQ charcoal, activated carbon, and industrial fuel, the coconut shell charcoal making machine has become a key investment for eco-friendly energy production.

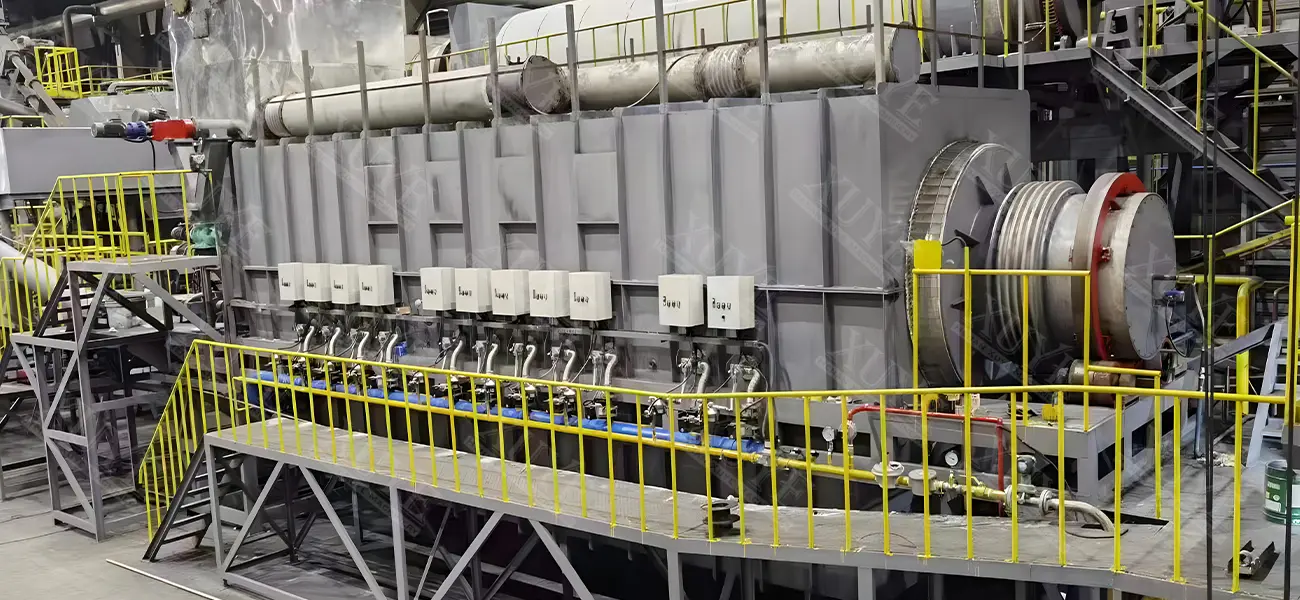

This advanced equipment adopts pyrolysis technology to convert raw coconut shells into charcoal under high temperature and limited oxygen conditions. Compared with traditional charcoal kilns, the modern coconut shell charcoal production equipment is energy-saving, environmentally friendly, and capable of producing multiple outputs such as charcoal, wood vinegar, tar, and syngas.

By turning coconut shell waste into a profitable resource, the coconut shell charcoal machine not only generates economic value but also contributes to waste recycling, renewable energy, and sustainable development.

A coconut shell charcoal making machine is a specialized piece of equipment that uses a process called pyrolysis to convert coconut shells into charcoal in an oxygen-deficient environment. Unlike traditional burning methods, pyrolysis prevents complete combustion, resulting in high charcoal yield and minimizing harmful emissions.

This machine is designed to handle the unique properties of coconut shells, which are hard and dense, making them ideal for producing charcoal with a high fixed carbon content.

The operation of a coconut shell charcoal making machine is a continuous and automated process, which can be broken down into several key stages:

Why should you consider this investment? The benefits are substantial:

The final product from your coconut charcoal making machine has diverse markets:

Selecting the right machine is crucial for your success. Consider these factors:

| Model | XY-800 | XY-1000 | XY-1200 | XY-1500 | XY-1800 | XY-2000 |

| Number of cylinder layers | Single | Single | Double | Double | Double | Double |

| Cylinder diameter | 800mm | 1000mm | 1200/700mm | 1500/900mm | 1800/1200mm | 2000/1500mm |

| Capacity | 200-300kg/h | 300-400kg/h | 450-600kg/h | 600-800kg/h | 800-1000kg/h | 1000-1200kg/h |

| Cylinder material | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L |

| Temerature | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC |

| Carbonization time | 20-60min | 20-60min | 20-60min | 20-60min | 20-60min | 20-60min |

| Raw material particle size | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm |

| Heating method | indirect heating | indirect heating | indirect heating | indirect heating | indirect heating | indirect heating |

| Operation mode | continuously working | continuously working | continuously working | continuously working | continuously working | continuously working |

| Control method | PLC control | PLC control | PLC control | PLC control | PLC control | PLC control |