Search the whole station

Biochar kiln is a specialized thermal processing system designed to convert organic biomass into biochar through pyrolysis or carbonization. Biochar, a stable form of carbon, has gained global attention for its role in soil improvement, carbon sequestration, and environmental remediation. A high-quality biochar kiln ensures that biomass such as wood, coconut shells, rice husks, and agricultural residues is converted efficiently, producing a product with high fixed carbon, large surface area, and excellent porosity.

As global demand for sustainable energy and carbon-negative technologies rises, biochar kilns have become essential equipment for farms, research institutes, and industrial production lines. In this article, we will explore the working principle, types, applications, advantages, and buying guide for biochar kilns, along with insights into the growing biochar industry.

A biochar kiln is essentially a carbonization furnace that operates under controlled heating and oxygen-limited conditions. Its main function is to break down biomass through thermal decomposition, driving off volatile compounds and leaving behind solid carbon. Unlike traditional open-pit burning, a kiln system ensures higher carbon retention, reduced emissions, and better control over the physical and chemical properties of the produced biochar.

Biochar kilns vary in design—from simple small-scale batch kilns for farmers to large industrial-scale continuous pyrolysis kilns. Depending on the feedstock and operational parameters, different kiln types can be chosen to meet specific production needs.

The working principle of a biochar kiln can be divided into several key stages:

The entire process requires careful control of temperature, residence time, and oxygen supply. Modern biochar production equipment integrates automated controls and sensors to ensure efficiency and consistency.

This is the most basic biochar kiln, often used in rural areas. Biomass is piled in a pit, covered with soil, and burned slowly. Although inexpensive, it has low efficiency and high emissions.

A batch kiln is a closed chamber where biomass is loaded, carbonized, and removed after completion. It is simple, affordable, and suitable for small farms or community-scale production.

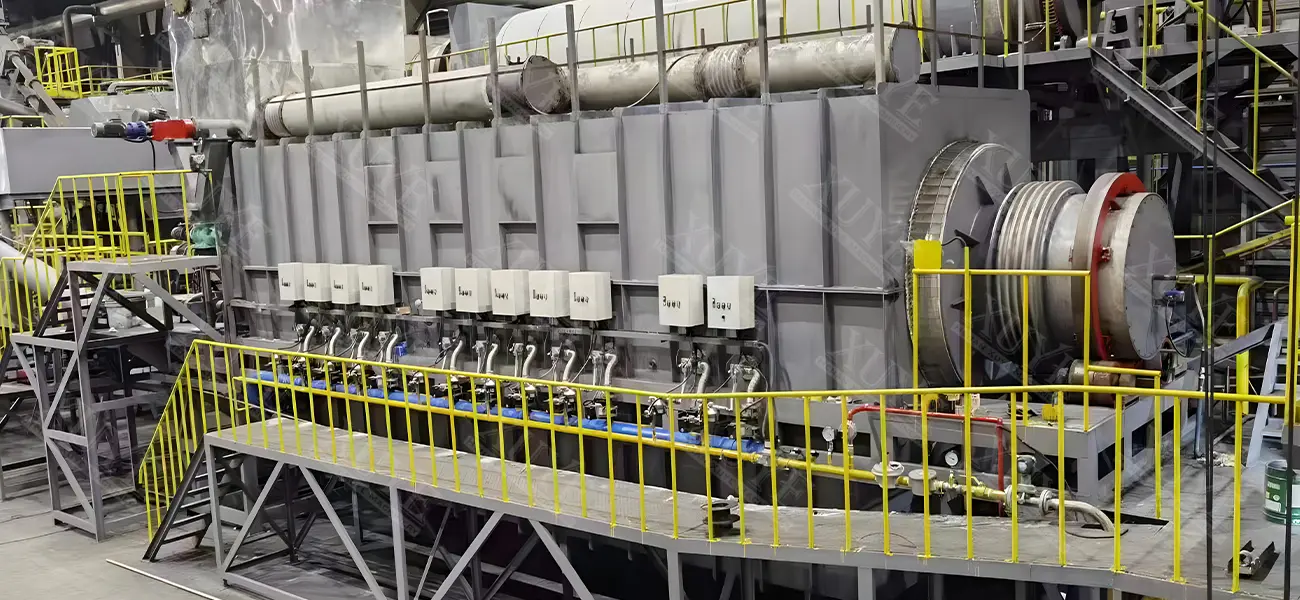

A continuous biochar kiln is designed for industrial-scale production. Biomass is continuously fed, and biochar is continuously discharged. These kilns, often rotary or screw-type furnaces, provide higher efficiency, stable quality, and energy recovery options.

Mobile kilns are portable units that can be transported to different farms or locations. They are ideal for decentralized biomass utilization and small-scale farmers.

This advanced kiln type operates under controlled pyrolysis, producing not only biochar but also bio-oil and syngas as valuable by-products. It is widely used in commercial applications and research.

When selecting a biochar kiln, consider the following factors:

| Model | XY-800 | XY-1000 | XY-1200 | XY-1500 | XY-1800 | XY-2000 |

| Number of cylinder layers | Single | Single | Double | Double | Double | Double |

| Cylinder diameter | 800mm | 1000mm | 1200/700mm | 1500/900mm | 1800/1200mm | 2000/1500mm |

| Capacity | 200-300kg/h | 300-400kg/h | 450-600kg/h | 600-800kg/h | 800-1000kg/h | 1000-1200kg/h |

| Cylinder material | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L |

| Temerature | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC |

| Carbonization time | 20-60min | 20-60min | 20-60min | 20-60min | 20-60min | 20-60min |

| Raw material particle size | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm |

| Heating method | indirect heating | indirect heating | indirect heating | indirect heating | indirect heating | indirect heating |

| Operation mode | continuously working | continuously working | continuously working | continuously working | continuously working | continuously working |

| Control method | PLC control | PLC control | PLC control | PLC control | PLC control | PLC control |